Stihl FS45C Review

Weve had a Stihl FS45C line trimmer / weed whacker for about 4 years, and even though it is made in China, found it to be quite good, and generally works as advertised. The American version seems to have had lots of issues with the carbs and US fuel blends. Others report that the line head's bronze bearing wears excessively quickly. Neither of those problems have occured with our unit.

The one issue we had right from the outset was that the "spark arrester" clogs about twice a year, and theres nothing mentioned about it in the manual, but it is easy to clean if you are OK getting your hands dirty. See this youtube video. The spark arrester is obviously ill conveived, and most people will be better off removing it altogether, as we have.

However last week, at about the 4 year old mark, the Mrs came in and told me it wasnt working. The motor was running but the head failed to turn. After cleaning the line feeder, and reassembling, it still did not turn. Upon further examination, it became clear that the drive tube end bearing assembly had developed an odd fault. The large nut that drives the cutting head was spinning on the axial, where it should be fixed. I thought to myself right off, we can land a man on the moon, but cant securely fasten two pieces of metal together?

So i took it to the local Stihl dealer where i was told that it needed an entire new drive tube assembly. He also said that it looked like a manufacturing defect that had sat there waiting to go. And that this was a problem he usually encountered only on cheap big box brands.

Not wanting to let reputable companies like this get away with such shoddy engineering, (and just as bad, large parts assemblys), i decided to go get it brazed or silver soldered at the local engineering shop. Even... if if cost the same as the part. However, a chance conversation with a friend about the Consumer Guarantees Act, (which says that products have to be fit for purpose, regardless of warranty), and i thought, heck, why not give Stihl a chance to see what sort of company they are.

So i sent Stihl NZ an email, explaining what had happened, and my planned solution. Now i know things break, and that nothing lasts forever, and i wasnt actually expecting them to replace the part for free, however Stihls reply was disappointing. And to anyone who knows anything at all about engineering, illogical.

"Thank you for your mail and enquiry.

We have had no listed issues with the heads to date. ( [Your local STIHL branch] are incorrect in their statement - "most likely a manufacturing defect "). It's not usual for the heads to fail but that depends on factors such as: nylon size, guard and knife in place, is it a STIHL design head, usage etc.

It is rated as a domestic machine only and the domestic warranty is two years from new."

In other words the standard line... its out of warranty. The obvious error, though, is that given that they "havent seen this issue before", thats all the more reason to suspect a diagnosis of an outlier manufacturing defect.

Anyway just to be clear we have always used the factory new guard and line head, and the correct line size exclusively. Our use case has been once a month for about two hours of green grass cutting. Like i said, the thing hasnt sat in the shed, and nothing lasts forever. But you have to wonder whether a response more like the following:

"We are sorry to hear this. Its unusual for that to happen, which suggests that it has perhaps failed early. We will look into the manufacturing process to ensure that this is avoided in the future. However given that your unit is so far out of warranty, the best we can do is to offer you a replacement part at cost price, and get it to you over night. Hope that is agreeable."

Would that have made us say, when it comes time to replace the trimmer, (or the MS231) in a couple years time: of course we will get another Stihl, their products and service have both been great? You bet. As it transpires, it looks like Stihl is becoming yet another Made in China. Our previous weed eater was a 100 dollar Homelite, and that outlasted the FS45.

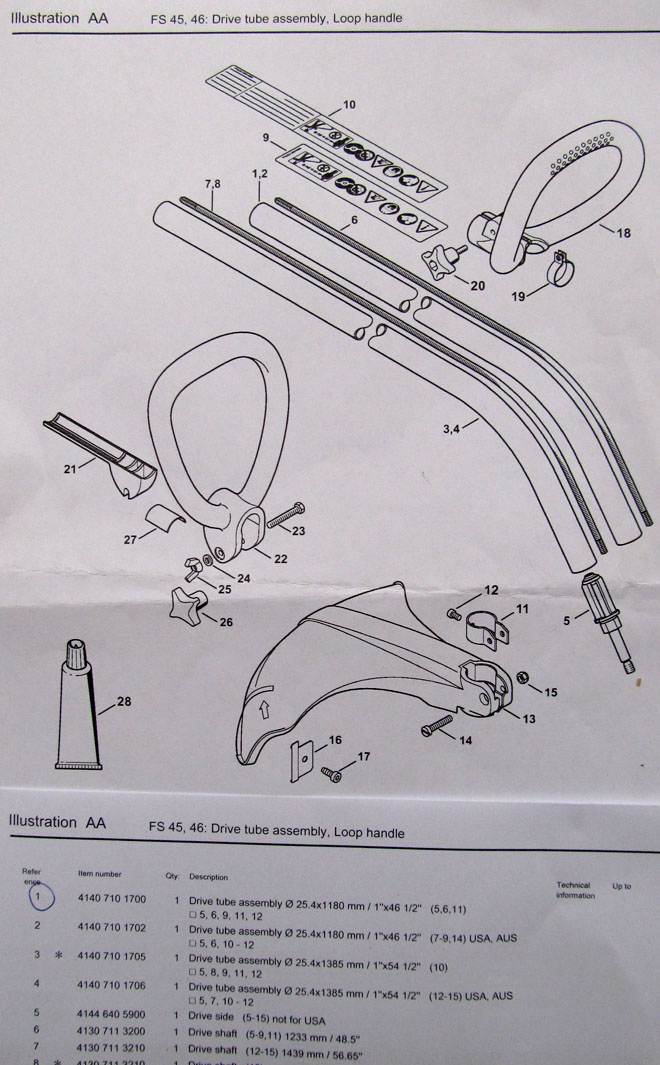

For anyone else encountering this issue, theres another video that shows how to remove the bearing assembly from the drive tube. Remove the torx screw that holds the metal u clamp, pull the bearing assembly out. To refit, pull the flexible drive shaft out enough to insert it into the bearing assembly and refit the shaft and bearing assembly into the drive tube.

And, it turns out that, according to Stihl NZ, you CAN get the bearing assembly as a seperate part if you persist, part number, 4140 640 1402. But silversolder is probably the best permanent solution, that wont damage the bearing or axial. Oh, and i wouldnt mess with the cir-clip on the shaft end of the assembly, it looks like it would be tricky to get off.

2015-10-13

www.zoneblue.nz/cms/page.php?view=stihl-fs45c-line-trimmer